How does Jiangsu Golden Morning Knitting Co., Ltd. ensure that every link of Film-Coated products from raw material procurement to finished product delivery meets high quality standards?

1. Raw material procurement

Supplier screening and evaluation

When selecting Film-Coated fabric suppliers, the company will conduct strict screening and evaluation. The company has a professional procurement team responsible for finding high-quality raw material suppliers worldwide. These suppliers must undergo multiple tests such as the company's field investigation, qualification review and sample testing to ensure that the raw materials they provide meet the company's quality standards.

Raw material testing

All purchased Film-Coated raw materials will undergo strict testing before entering the company. The testing content includes but is not limited to the chemical composition, physical properties, environmental performance and safety of the raw materials. Only raw materials that pass the test will be allowed to enter the production process.

2. Production process control

Advanced production equipment

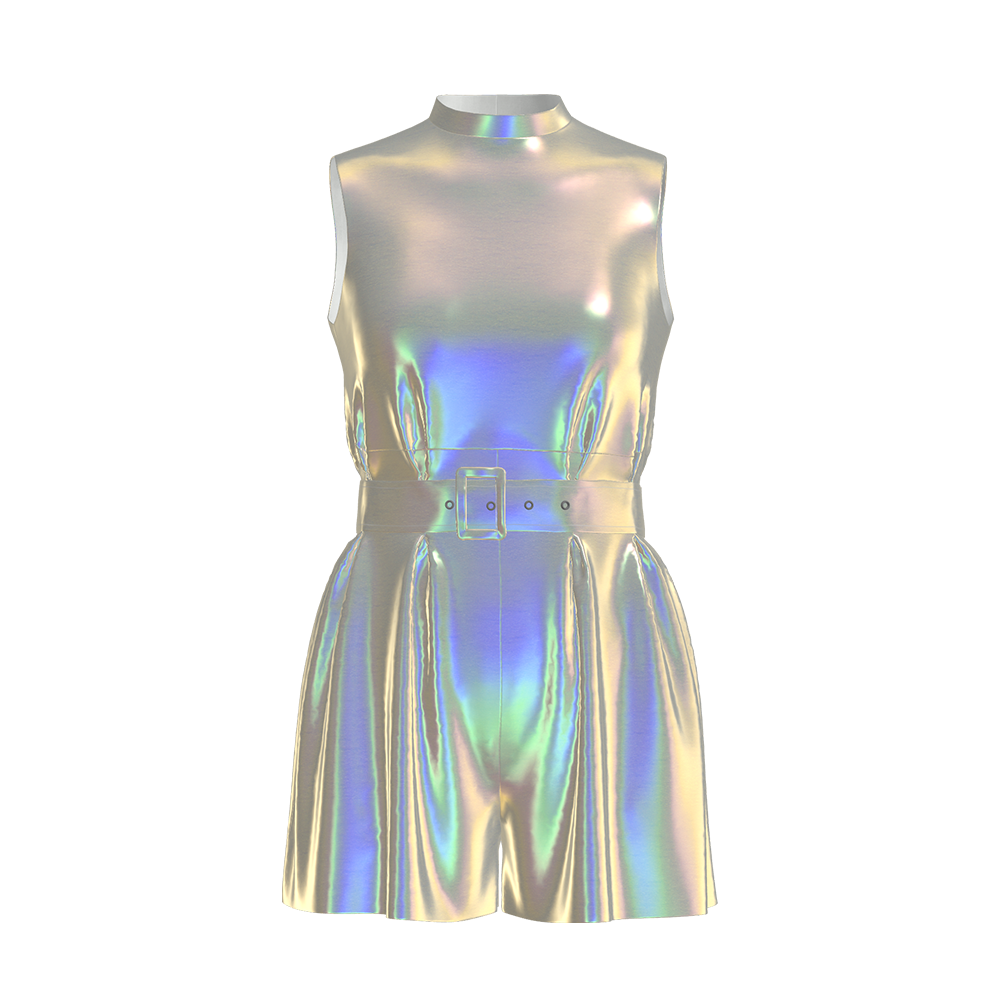

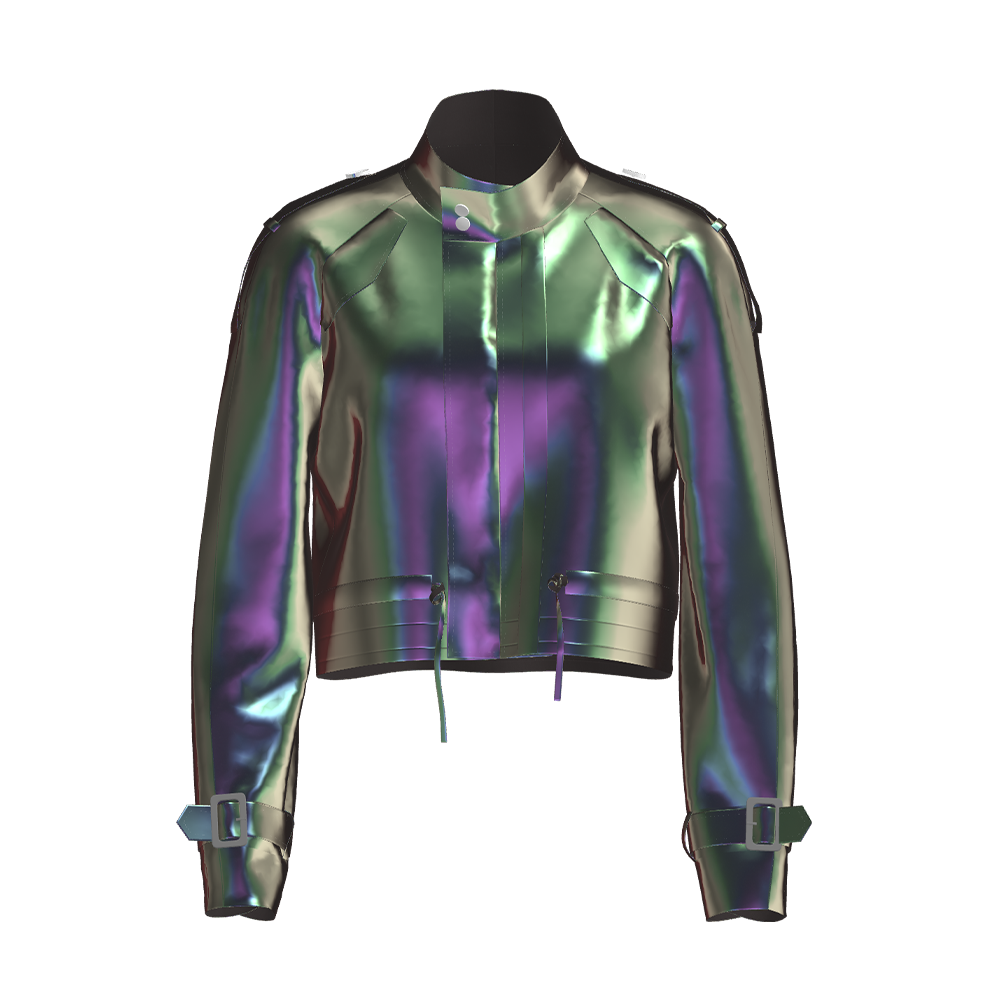

The company has introduced advanced production equipment and technology from home and abroad for the production of Film-Coated products. These equipment are not only high-precision and high-efficiency, but also can ensure that the products meet the best process parameters and quality requirements during the production process.

Strict process control

The company has formulated detailed process control standards, including production processes, operating specifications, quality monitoring points, etc. Production staff must strictly follow these standards to ensure that the products can meet the established quality requirements in every production link.

Quality Inspection and Monitoring

The company has set up a special quality inspection department to monitor and control the quality of Film-Coated products in real time during the production process. These tests include secondary inspection of raw materials, online inspection during the production process, and final inspection of finished products. Through this series of testing methods, the company can promptly discover and correct quality problems in the production process to ensure that the products meet high quality standards.

3. Finished product factory inspection

Finished product quality inspection

After the Film-Coated products are completed, the company will conduct a comprehensive quality inspection on them. These tests include appearance inspection, performance testing, environmental performance testing and other aspects. Only qualified products will be allowed to be sold from the factory.

Quality traceability system

The company has established a complete quality traceability system that can trace the quality of each batch of Film-Coated products. This system covers multiple links such as raw material procurement, production process control and finished product factory inspection, ensuring that the root cause of the problem can be quickly found and corresponding measures can be taken when quality problems occur.

4. Continuous Improvement and Innovation

Technology R&D and Innovation

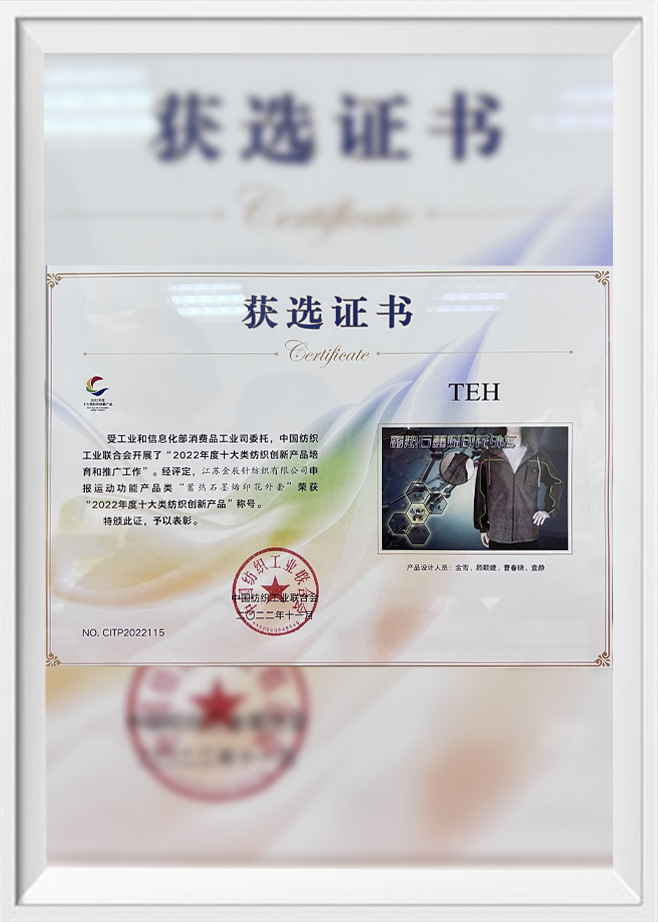

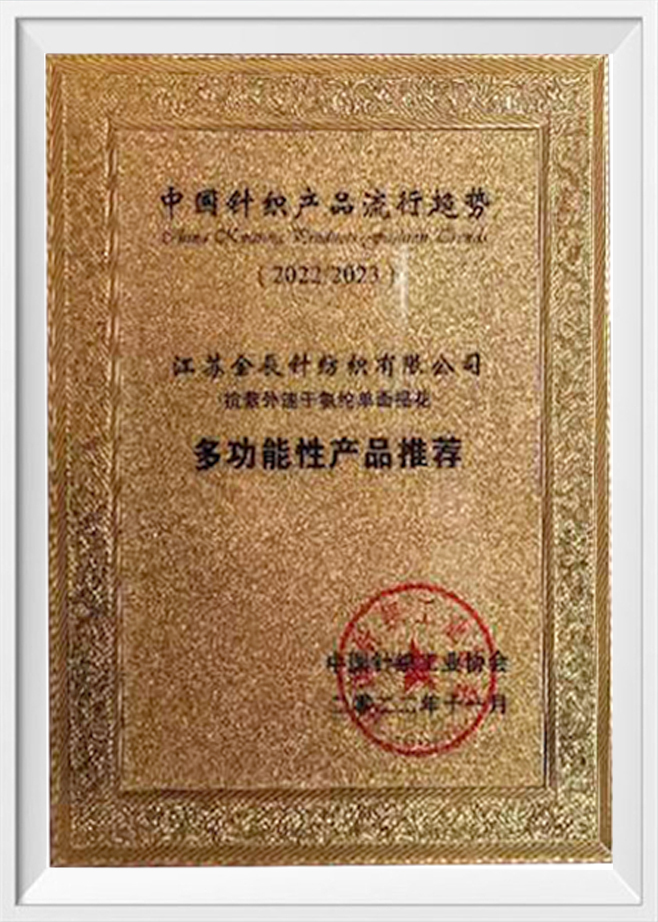

The company focuses on technology R&D and innovation, and continuously invests funds and resources in the technical upgrading and quality improvement of Film-Coated products. By introducing new technologies, new processes and new materials, the company can continuously improve the quality and competitiveness of its products.

Employee Training and Education

The company attaches great importance to employee training and education, and regularly organizes employee training in skills and quality management. Through training, employees can continuously improve their professional skills and quality awareness, providing strong guarantees for the production of high-quality products.

English

English 한국어

한국어 中文简体

中文简体

+86-512-52528088

+86-512-52528088 +86-512-14546515

+86-512-14546515